SAE J1942_201903 standard is developed through the cooperative efforts of the U.S. Coast Guard and SAE, became effective August 28,19911 , as the official document for nonmetallic flexible hose assemblies for commercial marine use.

SAE J1942 Standard covers specific requirements for several styles of hose and/or hose assemblies in systems aboard commercial vessels inspected and certificated by the U.S. Coast Guard. It is intended that this document establish hose constructions and performance levels that are essential to safe operations in the marine environment. Refer to SAE J1273 for selection, installation, and maintenance of hose and hose assemblies.

Refer to SAE J1527 for hose to convey gasoline or diesel fuel aboard small craft, including pleasure craft and related small commercial craft regulated directly or by reference under 33 CFR 183 Subpart J, and boats and yachts meeting American Boat and Yacht Council standards.

SAE J1942-1 is a listing of the products which have been certified for use in the applications described in SAE J1942, Table 1, for fluid power, fuel oil, lube oil, water, and pneumatic systems.

SAE J1942 references standards as follows:

SAE J343 Test and Test Procedures for SAE 100R Series Hydraulic Hose and Hose Assemblies

SAE J517 Hydraulic Hose

SAE J1273 Recommended Practices for Hydraulic Hose Assemblies

SAE J1475 Hydraulic Hose Fitting for Marine Applications

SAE J1527 Marine Fuel Hoses

SAE J1942-1 Qualified Hoses for Marine Applications

ASTM D1141-98 Specification for Substitute Ocean Water

MSHA 30 CFR 18.65 Conservation of Power and Water Resources - Subchapter B - Regulations Under the Federal Power Act

ISO 15541 Ships and Marine Technology - Fire Resistance of Hose Assemblies - Requirements for the Test Bench

HOSE APPLICATION/CONSTRUCTION

SAE J1942 Fittings shall conform to SAE J1475 where applicable. Only hose and fitting combinations that have been tested and passed the requirements of this document as hose assemblies are acceptable. Push-on fittings, quick disconnect couplings and fittings with a single worm-gear clamp, or a single band around the hose are unacceptable.

QUALIFICATION TESTS conform to SAE J343 except as noted.

IMMERSION-BURST TEST

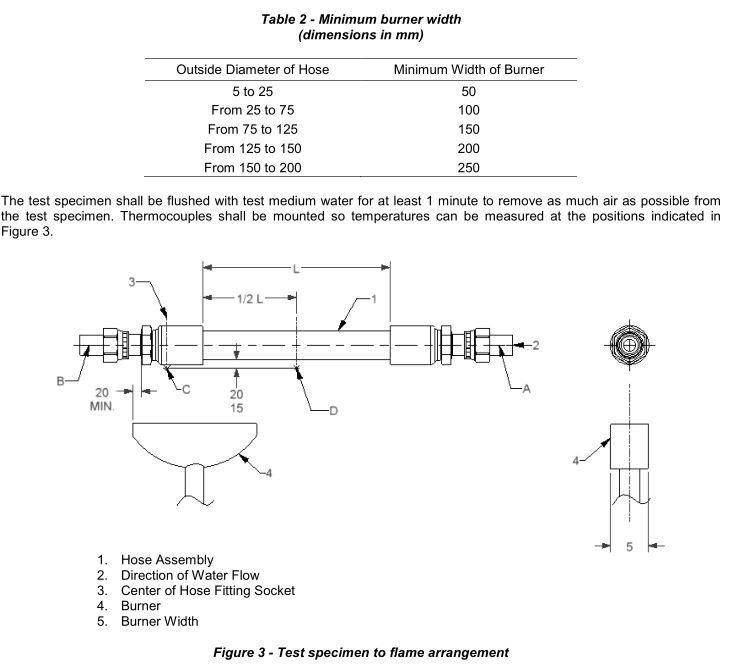

FLAME RESISTANCE TEST

FIRE RESISTANCE TEST including 2.5 Minute Fire Test, 30 Minute Fire Test,

NON-SAE J517 HOSE/HOSE ASSEMBLIES meet the following:

a. Proof Test per SAE J343. No leakage allowed.

b. Change in length per SAE J343. Not to exceed +2% and -4% (does not apply to wire helix-type hose).

c. Burst Test per SAE J343. Minimum burst shall be at least four times the maximum working pressure of the hose.

d. Cold Bend Test per SAE J343. No cracking or leakage allowed. Testing to be done at the manufacturer's minimum recommended temperature.

e. Impulse Test per SAE J343. Conduct test at 125% of maximum working pressure of the hose for 200000 cycles at a fluid temperature of 100 °C. No leakage or other malfunction is allowed. (Impulse not required on wire helix-type hose.)